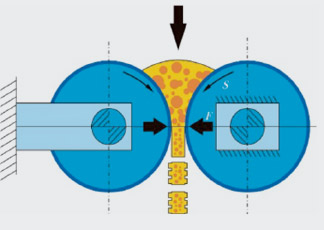

Design Principles

The CLM series high-pressure roller mill is a grinding equipment designed based on the principle of bed crushing. It mainly consists of a frame, roller system, hydraulic system, feeding device, control system, and transmission system. The roller system is divided into a movable roller system and a fixed roller system. The two roller systems rotate slowly relative to each other. The movable roller system applies pressure through a hydraulic cylinder and can move horizontally on the frame guide rail, crushing the material continuously fed into the gap between the two rollers, pressing it into cakes that fall outside the machine.

Structural Features

The roller surface features self-generated wear-resistant protection technology, forming a self-generated wear-resistant protective layer during use, resulting in a long service life for a single use. The roller surface is easy to maintain online, with short maintenance time and low cost, and the roller sleeve is replaceable. The design concept includes constant roller gap control within a certain pressure range and high-pressure roller load optimization control technology, solving the problems of material segregation and current over-limit trips in traditional high-pressure roller mills. This ensures material extrusion effectiveness while improving capacity and economy. The automatic control system is based on distributed fuzzy control principles and integrates specialized components from world-renowned suppliers, allowing local or remote control from the control room. It is simple, stable, safe, and reliable.

Product Advantages

Increased Production and Reduced Consumption: High crushing ratio and processing capacity, simple and quick maintenance, effectively improving output while reducing energy consumption and operating costs.

Flexible Configuration: Diverse product solutions, flexible process system configuration, and excellent cost performance.

Environmentally Friendly and Efficient: Material is crushed by static pressure, equipment runs smoothly with low noise and minimal dust pollution.

Equipment Selection

Note: The above-listed models are part of the CLM series high-pressure roller mills and are for reference only during selection. For details, please contact the company.

Technical Parameters

| Serial Number | Product Series | Model and Specification | Roller Diameter | Roller Width | Feed Particle Size | Feed Temperature | Motor Power |

| (mm) | (mm) | (mm) | (℃) | (Kw) | |||

| 1 | 120 Series | PFG120-45 | 1200 | 450 | <60 | <130 | 2×220 |

| 2 | 120 Series | PFG120-50 | 1200 | 500 | <60 | <130 | 2×250 |

| 3 | 120 Series | *PFG120-80 | 1200 | 800 | <25 | <100 | 2×250 |

| 4 | 140 Series | PFG140-65 | 1400 | 650 | <60 | <130 | 2×500 |

| 5 | 140 Series | PFG140-70 | 1400 | 700 | <60 | <130 | 2×500 |

| 6 | 140 Series | PFG140-80 | 1400 | 800 | <60 | <130 | 2×500 |

| 7 | 150 Series | PFG150-100 | 1500 | 1000 | <70 | <130 | 2×710 |

| 8 | 150 Series | PFG150-110 | 1500 | 1100 | <80 | <130 | 2×710 |

| 9 | 160 Series | PFG160-120 | 1600 | 1200 | <80 | <130 | 2×900 |

| 10 | 160 Series | PFG160-140 | 1600 | 1400 | <80 | <130 | 2×1120 |

| 11 | 180 Series | PFG180-160 | 1800 | 1600 | <80 | <130 | 2×1600 |

| 12 | 200 Series | PFG200-180 | 2000 | 1800 | <80 | <130 | 2×2000 |

Keywords

Next: Roller Press

Roller Press

Contact Information

Product Categories

Related Products

Related Products

Ball mill

Ball mill

Rod Mill

(Semi) Autogenous Mill

Mining Hoisting

Single-rope Winding Mine Hoist

Multi-rope friction mine hoist

Well Drilling Hoist

Supporting Equipment

Mining Washing and Selection

Selective Crusher

Centrifuge

-

WLL Series Coal Slime Scraper Discharge Centrifugal Dehydrator

-

WZY Series Dual-Mass Horizontal Vibrating Centrifugal Dehydrator

-

WZL Series Horizontal Vibrating Centrifugal Dehydrator

-

TWZ Series Horizontal Vibrating Centrifugal Dehydrator

-

LLS-900 Sludge Centrifugal Dehydrator

-

ML Series Coal Slurry Centrifugal Dewatering Machine

-

LL Series Vertical Centrifugal Dehydrator

Flotation machine

Filter machine

Grading Machine

Mining Auxiliary Equipment

Gear Reducer Series

-

Vertical mill gearbox

-

Special reducer for scraper machine

-

Industry-specific gear reducer

-

Bevel Gear Reducer

-

Cylindrical Gear Reducer

-

Planetary Gear Reducer

-

Parallel shaft reducer

-

Industrial General Gearbox Series

-

Helical Gear - Bevel Gear Reduction Motor

-

Helical Gear Reduction Motor

-

Planetary Gear Reducer

-

Cylindrical Gear Reducer

Category One

Category Two

Crusher Series

Rotary Crusher

Jaw Crusher

Impact Crusher

Cone Crusher

Ball Press Machine

High-pressure briquetting machine

Medium and High Pressure Briquetting Machine

Rotary kiln

-

Cement kiln (rotary kiln)

-

Light gray kiln (self-alkali steam calcination kiln)

-

Chemical kiln

-

Oxidation Cooling Kiln

-

Oxidative roasting rotary kiln (oxidation kiln)

-

Lithium Carbonate Rotary Kiln

-

Lime Rotary Kiln

-

Metal Magnesium Rotary Kiln

-

Architectural Lightweight Aggregate Rotary Kiln

-

Cement Rotary Kiln

Cast and forged parts

Large castings

Large Forgings

Transmission Accessories

Gear Coupling

Gear

Electro-hydraulic control system

Automation Control

-

GPRS Remote Expert Diagnostic System

-

Metallurgical Electrical Control Equipment

-

Automated Control System for Mineral Processing and Coal Washing

-

Local System Upgrade

-

Doubly-Fed Variable-Frequency Electric Control System

-

Fully digital DC control system

-

Fully digital low-voltage variable frequency feedback

-

Disc Brake Online Inspection System

-

Rotary Kiln Control System

Hydraulic System

-

Hydraulic System

-

Hydraulic System

-

Hydraulic System

-

Hydraulic System

-

Hydraulic System

-

Hydraulic system

-

Hydraulic system

-

Hydraulic System

-

Hydraulic System

-

Hydraulic Station

-

Variable-frequency servo hydraulic system

-

E119A/E119S, E118A/E118S Explosion-Proof Secondary Brake Hydraulic Station

-

Constant-Deceleration Electro-Hydraulic Braking Control System

-

TE160/TE161/TE162/TE163 Insert-Mounted Control Dual-Stage Braking Hydraulic Station

Hydraulic cylinder

Other accessories

Large welded components

-

Large kiln body riveted and welded components

-

Large furnace riveted and welded components

-

Large Riveted and Welded Components

-

Large Riveted and Welded Components

-

Large Riveted and Welded Components

-

Large steel ladle riveted and welded components

-

Large base

-

Large Riveted and Welded Components

-

Ball Mill Cylinder

Wear-resistant products

-

Eccentric Crusher Jaw Plate

-

New-Type High-Pressure Roller Wear-Resistant Surfacing Welding Technology

-

Bus Alloy Bushings

-

Large ball mill ZGMN13CR2 lining plate

-

Medium-chromium alloy liner plate

-

High-manganese steel product series

-

High-precision cast iron parts

-

Low-carbon martensitic steel jaw plate

-

Large Self-Grinding Mill Cylinder Lining Plates

Engineering Plastics

-

Modified PP sheave and guide wheel lining blocks for elevators

-

Nylon products

-

Polyurethane Products

-

Multi-rope hoist phenolic press blocks, fixing blocks

-

Germany-imported — LUWIPLAST GELB848 Friction Pads

-

Single-rope mine hoist plastic lining板

-

WSM-3 New Eco-Friendly, Non-Asbestos Brake Blocks (Elevator Braking System)

-

KP-09 Ultra-High Molecular Wheel Sheave Lining Pads

-

GDM326 Imported Material High-Performance Friction Pads

Roller shaft

crane sheave

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

CITICTLC

Learn more about dynamic information