Product Details

Design Principle

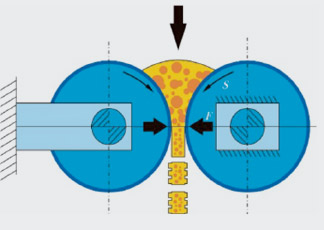

The CLM series high-pressure roller mill is a powder grinding equipment designed based on the principle of material bed crushing. It mainly consists of a frame, roller system, hydraulic system, feeding device, control system, and transmission system. The roller system is divided into a moving roller system and a fixed roller system. The two roller systems rotate slowly relative to each other. The moving roller system can move horizontally on the frame guide rail through a hydraulic cylinder, so that the materials continuously fed into the gap between the two rollers are crushed and pressed into a cake and fall out of the machine.

Structural Features

Roller surface self-generating wear-resistant protection technology forms a self-generating wear-resistant protective layer during use, with a long single-use life. Online maintenance of the roller surface is simple, short, and low-cost, and the roller sleeve can be replaced. The design concept of constant roller gap control within a certain pressure range and the high-pressure roller load optimization control technology solve the problems of traditional high-pressure roller mills caused by material segregation and current overlimit shutdown, improving production capacity and economy while ensuring material extrusion effect. The automatic control system based on distributed fuzzy control principle and integrated with dedicated components from world-renowned suppliers can be controlled locally or remotely from the control room, which is simple, stable, safe, and reliable.

Product Advantages

-

Increased production and reduced consumption: Large crushing ratio and processing capacity, simple and quick maintenance, effectively increase output, reduce energy consumption and operating costs.

-

Flexible configuration: Diverse product solutions, flexible process system configuration, superior cost performance.

-

Environmentally friendly and efficient: Materials are crushed by static pressure, the equipment runs smoothly, the noise is low, and there is less dust pollution.

Equipment Selection

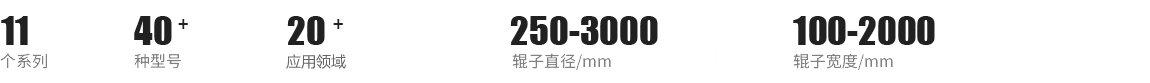

Note: The above are some models of the CLM series high-pressure roller mills, for reference only. Please contact the company for details.

Technical Parameters

| Serial Number |

Product Series |

Model, Specification |

Roller Diameter |

Roller Width |

Feed Size |

Feed Temperature |

Motor Power |

| ( mm ) |

( mm ) |

( mm ) |

( ℃ ) |

( Kw ) |

|||

| 1 |

120 Series |

PFG120-45 |

1200 |

450 |

<60 |

<130 |

2 × 220 |

| 2 |

PFG120-50 |

1200 |

500 |

<60 |

<130 |

2 × 250 |

|

| 3 |

'*PFG120-80' |

1200 |

800 |

<25 |

<100 |

2 × 250 |

|

| 4 |

140 Series |

PFG140-65 |

1400 |

650 |

<60 |

<130 |

2 × 500 |

| 5 |

PFG140-70 |

1400 |

700 |

<60 |

<130 |

2 × 500 |

|

| 6 |

PFG140-80 |

1400 |

800 |

<60 |

<130 |

2 × 500 |

|

| 7 |

150 Series |

PFG150-100 |

1500 |

1000 |

<70 |

<130 |

2 × 710 |

| 8 |

PFG150-110 |

1500 |

1100 |

<80 |

<130 |

2 × 710 |

|

| 9 |

160 Series |

PFG160-120 |

1600 |

1200 |

<80 |

<130 |

2 × 900 |

| 10 |

PFG160-140 |

1600 |

1400 |

<80 |

<130 |

2 × 1120 |

|

| 11 |

180 Series |

PFG180-160 |

1800 |

1600 |

<80 |

<130 |

2 × 1600 |

| 12 |

200 Series |

PFG200-180 |

2000 |

1800 |

<80 |

<130 |

2 × 2000 |

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

Luoyang Kunju

Learn more about dynamic information