Product Details

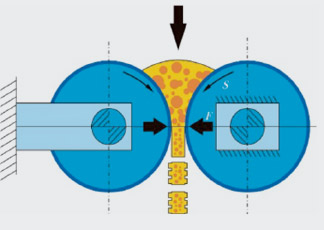

Design Principle

The CLM series high-pressure roller mill is a pulverizing equipment designed based on the principle of material bed pulverization. It mainly consists of a frame, roller system, hydraulic system, feeding device, control system, and transmission system. The roller system is divided into a moving roller system and a fixed roller system. The two roller systems rotate slowly relative to each other. The moving roller system can move horizontally on the frame guide rail through a hydraulic cylinder, so that the materials continuously fed into the gap between the two rollers are crushed and pressed into a material cake that falls outside the machine.

Structural Features

Roller surface self-generating wear-resistant protection technology forms a self-generating wear-resistant protective layer during use, resulting in a long service life. Online maintenance of the roller surface is simple, fast, and low-cost, and the roller sleeve is replaceable. The design concept of constant roller gap control within a certain pressure range and the high-pressure roller load optimization control technology solve the problems of traditional high-pressure roller mills caused by material segregation and current over-limit shutdown. While ensuring the material extrusion effect, it improves productivity and economy. The automatic control system, based on the distributed fuzzy control principle and integrating special components from world-renowned suppliers, can be controlled locally or remotely from the central control room, and is simple, stable, safe, and reliable.

Product Advantages

-

Increased Production and Reduced Consumption: Large crushing ratio and processing capacity, simple and quick maintenance, effectively increase output, reduce energy consumption and operating costs.

-

Flexible Configuration: Diverse product solutions, flexible process system configuration, and superior cost performance.

-

Environmentally Friendly and Efficient: Materials are crushed by static pressure, the equipment runs smoothly, the noise is low, and there is little dust pollution.

Equipment Selection

Note: The above are some models of the CLM series high-pressure roller mills, for reference only. Please contact the company for details.

Technical Parameters

| Serial Number |

Product Series |

Model, Specification |

Roller Diameter |

Roller Width |

Feed Size |

Feed Temperature |

Motor Power |

| ( mm ) |

( mm ) |

( mm ) |

( ℃ ) |

( Kw ) |

|||

| 1 |

120 Series |

PFG120-45 |

1200 |

450 |

<60 |

<130 |

2 × 220 |

| 2 |

PFG120-50 |

1200 |

500 |

<60 |

<130 |

2 × 250 |

|

| 3 |

'*PFG120-80' |

1200 |

800 |

<25 |

<100 |

2 × 250 |

|

| 4 |

140 Series |

PFG140-65 |

1400 |

650 |

<60 |

<130 |

2 × 500 |

| 5 |

PFG140-70 |

1400 |

700 |

<60 |

<130 |

2 × 500 |

|

| 6 |

PFG140-80 |

1400 |

800 |

<60 |

<130 |

2 × 500 |

|

| 7 |

150 Series |

PFG150-100 |

1500 |

1000 |

<70 |

<130 |

2 × 710 |

| 8 |

PFG150-110 |

1500 |

1100 |

<80 |

<130 |

2 × 710 |

|

| 9 |

160 Series |

PFG160-120 |

1600 |

1200 |

<80 |

<130 |

2 × 900 |

| 10 |

PFG160-140 |

1600 |

1400 |

<80 |

<130 |

2 × 1120 |

|

| 11 |

180 Series |

PFG180-160 |

1800 |

1600 |

<80 |

<130 |

2 × 1600 |

| 12 |

200 Series |

PFG200-180 |

2000 |

1800 |

<80 |

<130 |

2 × 2000 |

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

Luoyang Kunju

Learn more about dynamic information