Medium and high pressure ball machine

Keyword:

Classification:

Product Details

Product Introduction

The ZY series medium-pressure briquetting machine is a commonly used equipment for pressing powdery materials into shapes. It is a briquetting equipment that relies on the material's self-weight to enter the roll pressing area to form briquettes with higher bulk density, mainly used

for materials with a line pressure ratio of 1-3t/cm, such as solid waste, hazardous waste, construction waste, urban sludge, shaped coal, coking coal, coke, shaped carbon, refractory materials, etc.

Product Advantages

The pressing area of the medium-pressure briquetting machine consists of two roller assemblies rotating in opposite directions at the same speed. One roller assembly is fixed, while the other is a movable roller supported on the frame by a hydraulic system. The surface of the rollers has custom molds. When materials are continuously fed into the gap between the rollers, they are compressed and formed. As the design basis of the briquetting machine, the line pressure ratio is the most important (unit: N/m or t/cm). We have mature experience with the line pressure ratio for most materials, while for new materials, we mainly determine their line pressure ratio through experimental means.

Working Principle

The medium-pressure briquetting machine transmits power to the two rollers through a reducer, making them rotate towards each other. During the rotation, the material naturally enters the ball mold on the rollers. As the rollers rotate, the pressure on the material gradually increases. When the material rotates to the line contact point of the two rollers, the pressure reaches its peak. Under the action of enormous line pressure, the powdery material is formed into balls.

状。

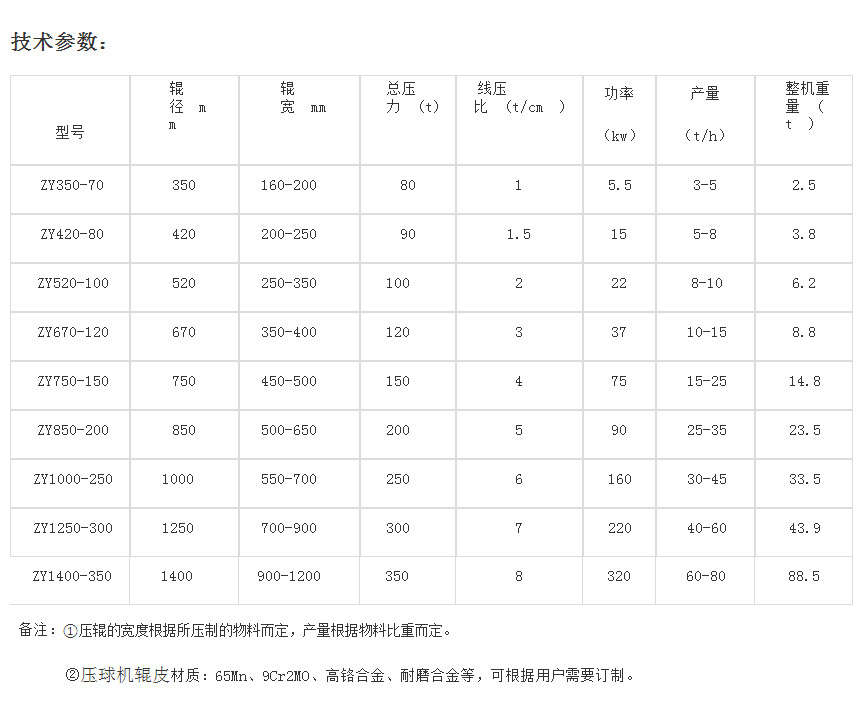

Technical Parameters

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

Luoyang Kunju

Learn more about dynamic information