Single-rope winding hoist

Keyword:

Classification:

Product Details

This product is designed and manufactured in accordance with the enterprise standard Q/HBWF003 "Single-rope winding mine hoist", industry standard AQ1035-2007 "Safety inspection code for single-rope winding mine hoists used in coal mines", national standard GB/T20961-2007 "Single-rope winding mine hoists", and the "Coal Mine Safety Regulations".

Scope of Application

Single-rope winding mine hoists are mainly used for hoisting coal, materials, personnel, and lowering materials and equipment in vertical or inclined shafts of coal, metal, and non-metal mines, and can also be used for other traction transportation.

Working Principle

The motor transmits power to the drum winding the steel wire rope through the reducer to achieve the lifting and lowering of the container; speed regulation is achieved through electrical control; the disc brake is braked by hydraulic and electrical control; the depth indication of the lifting container is realized through various position indication systems; the entire machine is monitored and protected through a combined mechanical, electrical, and hydraulic control system composed of various sensors and control components; information transmission inside and outside the hoist is achieved through computer and network technology.

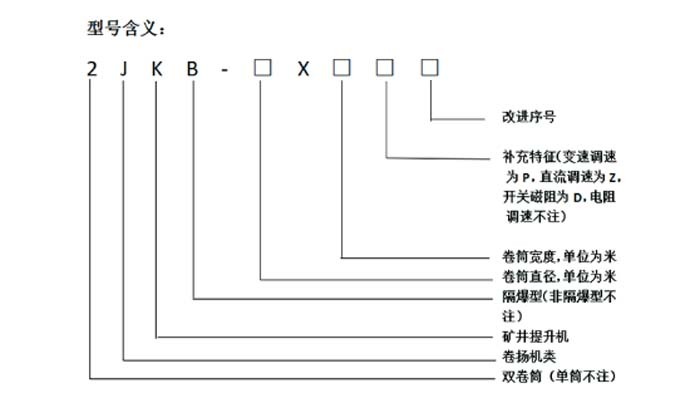

Model Meaning

Example 1: Drum diameter 3.0m  ,width 1.5m, the product model of a double-drum single-rope winding mine hoist using frequency conversion speed regulation is: 2JK-3.0×1.5P.

,width 1.5m, the product model of a double-drum single-rope winding mine hoist using frequency conversion speed regulation is: 2JK-3.0×1.5P.

Example 2: Drum diameter 2.5m, width 2.0m, the product model of a single-drum single-rope winding mine hoist using explosion-proof frequency conversion speed regulation is: JKB-2.5×2.0P.

Single-Rope Winding Mine Hoist Main Shaft Assembly

The main shaft assembly is the working mechanism of the hoist and also the main load-bearing component. It bears the entire torque of the hoist, winding the lifting steel wire rope to withstand various loads. It is mainly composed of the main shaft, bearings, bearing housings, drum, sheave, liner, high-strength bolt assembly, etc. The main shaft is forged from 45# carbon steel, undergoes two non-destructive testing inspections and mechanical performance tests, meets national standards, ensures reliable performance, and except for the connection with the coupling, no keyways are opened on the main shaft, ensuring both strength and rigidity, greatly improving the safety and extending the service life; the main shaft bearings use domestic Harbin, Wuhan, and Luoyang bearings, reliable operation, and improved rotation efficiency.

The drum is welded from low-carbon alloy steel plates. The deformation produced by the drum under load can be quickly diffused, and the stress deformation is not concentrated, effectively improving the load-bearing capacity and fatigue strength of the drum. After welding, the drum undergoes aging vibration to eliminate internal stress and prevent drum deformation; the brake discs are all made of 16Mn plates, with good deformation resistance and wear resistance. It can be made into a split type according to user needs. All split drums and brake discs are manufactured in the factory and can be used after installation at the site of use without any further processing.

The double-drum hoist uses a radial tooth hydraulic rope adjustment method. When adjusting the rope, it is easily controlled through the operating table, using hydraulic pressure to actuate the clutch, so that the main shaft and the moving drum generate relative movement, and the rope adjustment is fast and reliable.

There are several structural types of drums:

① Integral welded structure. The drum of this type is integrally welded, and the brake disc is also welded to the drum.

② Integral welded structure. The brake disc is a split two-瓣 brake disc connected to the drum with high-strength bolts.

③ The drum is a split welded drum. The drum is a split two-瓣 or four-瓣 type, and the brake disc is a split two-瓣 brake disc connected to the drum with high-strength bolts.

Technical Parameters

Serial Number |

Product Model |

Drum |

Steel Wire Rope |

Steel Wire Rope |

Wire |

Wire |

Lifting Height or Transportation |

Maximum |

Motor |

|||||||

Number |

Diameter |

Width |

Two Drums |

Personnel |

Cargo |

Personnel |

Cargo |

Single Layer |

Double Layer |

Triple Layer |

||||||

m |

kN |

m |

kN |

m |

m/s |

r/min |

||||||||||

1 |

JK-2×1.5 |

1 |

2.0 |

1.50 |

|

44 |

61 |

44 |

61 |

24 |

396.5 |

295 |

586 |

914 |

5.2 |

1000 |

2 |

JK-2×1.5P |

|||||||||||||||

3 |

JK-2×1.8 |

1.80 |

366 |

730 |

1132 |

|||||||||||

4 |

JK-2X1.8P |

|||||||||||||||

5 |

JK-2×2.0P |

2.00 |

370 |

815 |

1260 |

|||||||||||

6 |

JK-2.5×2 |

2.5 |

69 |

83 |

69 |

83 |

30 |

621 |

403 |

802 |

1245 |

5.0 |

750 |

|||

7 |

JK-2.5×2P |

|||||||||||||||

8 |

JK-2.5×2.3 |

2.30 |

473 |

944 |

1460 |

|||||||||||

9 |

JK-2.5×2.3P |

|||||||||||||||

10 |

JK-3.0×2.2 |

3.0 |

2.20 |

100 |

135 |

100 |

135 |

36 |

900 |

447 |

887 |

1378 |

6.0 |

|||

11 |

JK-3.0×2.2P |

|||||||||||||||

12 |

JK-3.0×2.5 |

2.50 |

518 |

1030 |

1596 |

|||||||||||

13 |

JK-3.0×2.5P |

|||||||||||||||

14 |

JK-3.5×2.5 |

3.5 |

135 |

170 |

135 |

170 |

43 |

1230 |

513 |

1017 |

One |

6.9 |

||||

15 |

JK-3.5×2.5P |

|||||||||||||||

16 |

JK-3.5×2.8 |

2.80 |

584 |

1161 |

One |

|||||||||||

17 |

JK-3.5×2.8P |

|||||||||||||||

18 |

JK-4×2.5P |

4.0 |

2.5 |

218 |

245 |

218 |

245 |

50 |

1962 |

492 |

1028 |

1622 |

14 |

600 |

||

| 19 | JK-4×2.7P | 2.7 | 532 | 1110 | 1752 | |||||||||||

| 20 | JK-4×3P | 3.0 | 592 | 1233 | 1947 | |||||||||||

| Note 1: The maximum lifting speed is an estimated value based on the nominal diameter of the drum and single-layer winding; Note 2: The maximum lifting speed must not exceed the provisions in the table and AQ1035-2007, 5.2.13~5.2.15; Note 3: The lifting height or transport length listed in the table is calculated based on the maximum wire rope diameter in the table; Note 4: The ratio of the drum diameter to the wire rope diameter for the hoist should not be less than 80; the ratio of the drum diameter to the wire rope diameter for the shaft hoist should not be less than 60. |

||||||||||||||||

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

Luoyang Kunju

Learn more about dynamic information