Multi-rope friction hoist

Keyword:

Classification:

Product Details

The multi-rope friction hoist series products are manufactured according to the enterprise standard Q/HBWF006 "Multi-rope Friction Hoist", AQ1036-2007 "Safety Inspection Standard for Multi-rope Friction Hoists Used in Coal Mines", GB/T10599—2010 "Multi-rope Friction Hoists", and the "Coal Mine Safety Regulations".

Product Use and Application Range

Multi-rope friction mine hoists are classified into tower-type and ground-type according to their installation methods. They are mainly used in coal, metal, and non-metal mines for vertical shafts to lift and lower materials, personnel, and equipment.

Since the electrical equipment of this product is non-explosion-proof, it cannot be used in places with flammable and explosive media such as gas and coal dust.

Working Principle

The multi-rope friction hoist uses the principle of flexible body friction transmission. The steel wire rope is placed on the friction wheel, and the friction between the steel wire rope and the friction lining is used to lift and lower heavy objects or personnel.

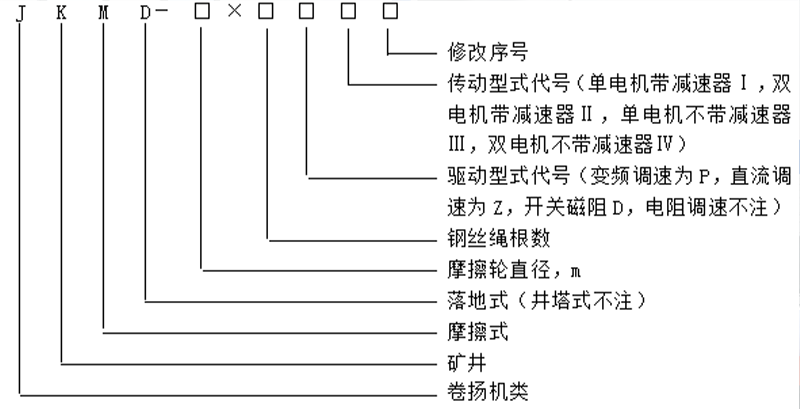

Product Model Example

Multi-rope Friction Hoist Main Shaft Assembly

The main shaft assembly is the working mechanism of the hoist, bearing all the torque for lifting and lowering loads, and withstanding the tensile force of the steel wire ropes on both sides of the friction wheel. It consists of the main shaft, friction wheel, rolling bearing, bearing housing, bearing cover, bearing beam, friction lining, fixing block, and pressure block.

The main shaft is one of the main parts of the main shaft assembly. It bears the weight of the entire main shaft assembly, external loads, and transmits all torque. It is forged from low-alloy steel. One or two flanges are directly forged on the shaft and connected to the friction wheel via high-strength bolts.

The friction wheel uses integral low-alloy steel, with an all-welded structure, consisting of a cylinder shell, left and right radial plates, left and right hubs, support rings, and rope-blocking plates. For large hoists (diameter greater than or equal to 2.8m), support rings are welded inside the cylinder shell to strengthen the stiffness of the entire cylinder shell. According to customer needs, a non-detachable welded brake disc (also known as a dead brake disc) can be used, that is, the brake disc is welded to the end of the drum, or a detachable combination brake disc can be used, that is, the brake disc is made into two halves and installed on the friction wheel, and the friction wheel and the brake disc are connected by high-strength bolts. The brake disc is divided into single and double brake discs.

The main bearing consists of rolling bearings, bearing covers, bearing housings, bearing end caps and other components. The rolling bearings use domestic well-known brands such as Harbin, Wafangdian, and Luoyang double-row self-aligning ball roller bearings. They have good self-aligning performance, can withstand large radial loads and impact resistance, have a long lifespan, high efficiency, and convenient maintenance.

The friction lining is a key component. The friction lining is fixed to the friction wheel using bolts and fixing blocks and pressure blocks. Wanfeng Company uses high-friction linings with a friction coefficient ≥0.25 to ensure the performance parameters, lifting capacity, and safety and reliability of the hoist. The ground-type hoist lining has two rope grooves, and the steel wire rope is switched between the two rope grooves through a rope-shifting device, which can double the lifespan of the friction lining and improve the utilization rate of the lining material.

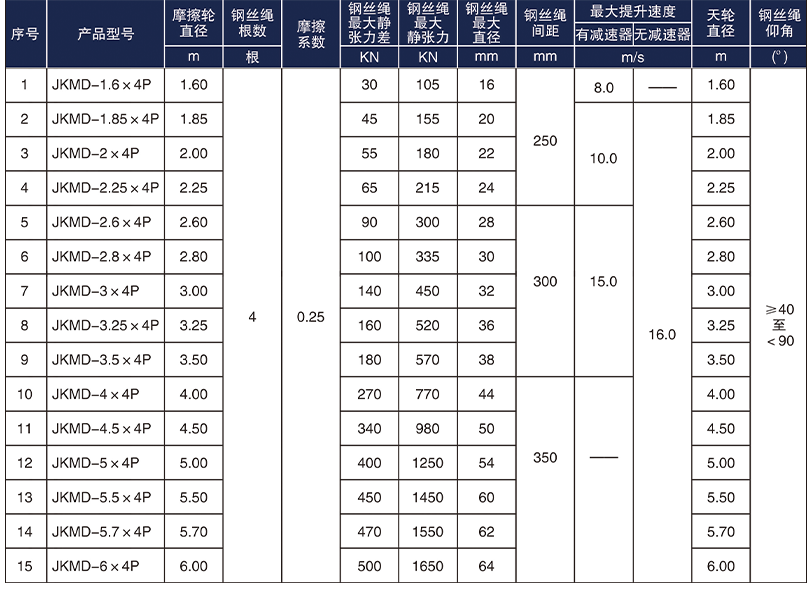

Technical Parameters

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

Luoyang Kunju

Learn more about dynamic information