Planetary gear reducer

Keyword:

Classification:

Product Details

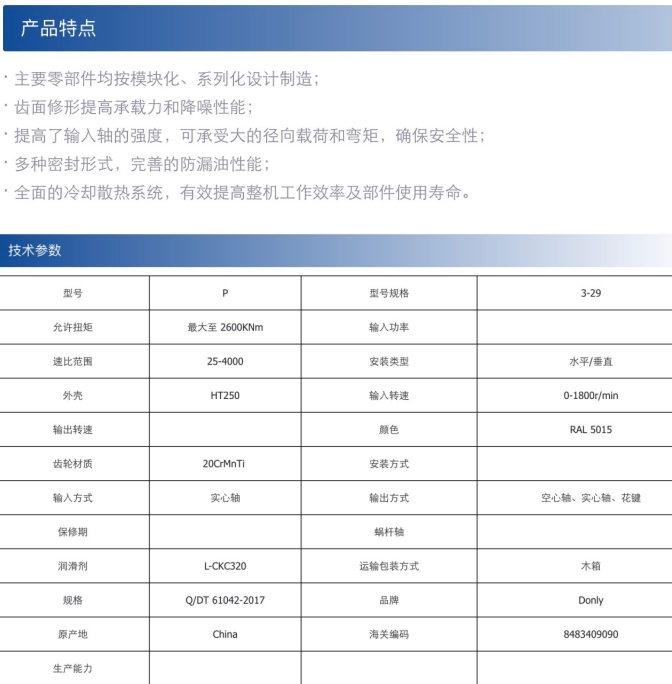

At the heart of the Planetary Gear Reducer lies its distinctive planetary gear train structure. Comprising a central sun gear, multiple planet gears orbiting around the sun gear, and an outer ring gear, this configuration allows for a more complex and efficient power transmission process. The planet gears mesh simultaneously with the sun gear and the ring gear, distributing the load evenly across multiple gear teeth. This results in a higher torque-carrying capacity compared to single-stage or parallel-shaft gear reducers, enabling the planetary gear reducer to handle heavy loads with ease while maintaining a relatively small size and weight.

Precision is another key attribute of the Planetary Gear Reducer. The precisely engineered gear geometry and tight manufacturing tolerances ensure smooth and accurate motion transmission. The low backlash design of many planetary gear reducers minimizes the play between the gears, providing more precise control over the output speed and position. This is crucial in applications such as robotics, CNC machining, and servo systems, where even the slightest deviation in motion can affect the quality of the final product. The high precision of the planetary gear reducer also contributes to its long service life, as it reduces the stress and wear on the gears, enhancing overall reliability.

The efficiency of the Planetary Gear Reducer is a major factor in its widespread adoption. The multi-stage power transmission through the planetary gear train allows for higher reduction ratios in a more compact space, reducing energy losses during the transmission process. Additionally, the optimized gear tooth profiles and lubrication systems further improve the efficiency of the reducer, minimizing friction and heat generation. This not only saves energy but also reduces the operating costs associated with running industrial machinery. In applications where energy consumption is a significant concern, such as in wind turbines and electric vehicles, the use of planetary gear reducers can lead to substantial energy savings and improved performance.

When integrated with an Industrial General-Purpose Gearbox, the Planetary Gear Reducer can further expand the capabilities of the mechanical system. The general-purpose gearbox provides the basic framework for power transmission, while the planetary gear reducer offers the additional precision and torque-boosting capabilities. This combination is particularly useful in applications that require a combination of high torque, precise speed control, and adaptability to different working conditions. For example, in material handling equipment, the industrial general-purpose gearbox can be used to transmit power from the motor to the main drive system, while the planetary gear reducer can be employed to provide the necessary speed reduction and torque increase for lifting and moving heavy loads with accuracy.

Product Query

Leave contact information and get free product quotation.

Contact Us

No.99 Hengshan Road, Jianxi District, Luoyang City, Henan Province

sweep

CITICTLC

Learn more about dynamic information